Energy Efficiency of UPVC

UPVC: Revolutionizing Energy Efficiency in Construction with Sustainable Solutions

Table of Contents

UPVC, or unplasticized Polyvinyl Chloride, has become a popular choice in the construction industry, especially for window frames and doors, due to its exceptional energy efficiency. This material stands out for its robust insulation capabilities, which play a significant role in reducing energy consumption in buildings. Not only is UPVC cost-effective and durable, but its low thermal conductivity also means better retention of heat in winter and cool air in summer, leading to lower energy bills and a smaller carbon footprint. As we delve deeper into the world of UPVC, we’ll explore its benefits, environmental impact, and how it compares to other materials on the market.

Understanding UPVC and its Benefits

The Insulation Advantage of UPVC

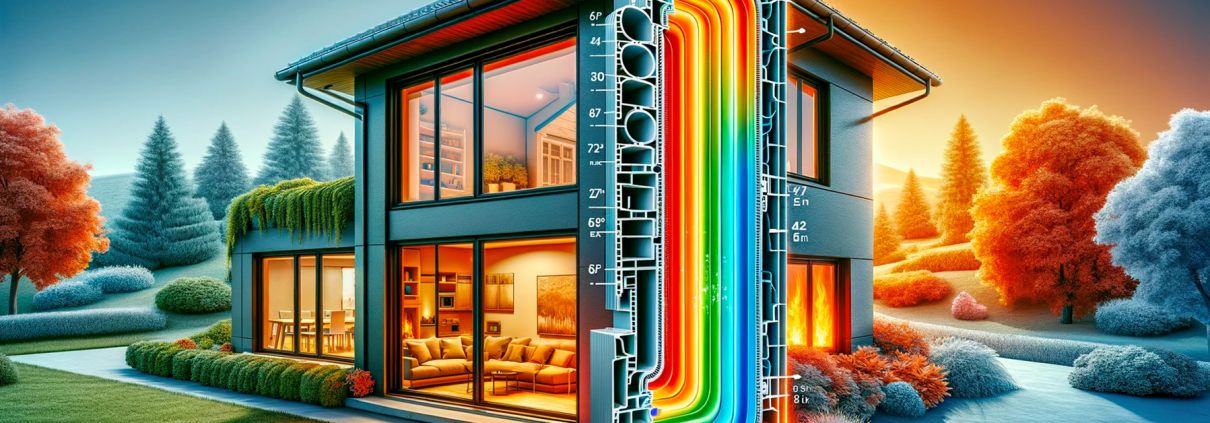

One of the primary benefits of UPVC is its outstanding thermal insulation. This characteristic is crucial in maintaining a stable indoor temperature, leading to less reliance on heating and cooling systems. Consequently, this reduces energy bills and lowers carbon emissions. The secret lies in the material’s structure, which includes multiple chambers that trap air, forming an effective barrier against heat transfer. Unplasticized Polyvinyl Chloride, or UPVC, is a versatile material widely used in the construction industry, particularly for window frames and doors. Its popularity stems from its robustness, cost-effectiveness, and excellent insulation properties. Unlike traditional materials, UPVC does not warp or rot, making it a long-lasting choice for homeowners. Additionally, its low thermal conductivity makes it an excellent insulator, contributing to reduced energy consumption in buildings.

Noise Reduction Qualities

In addition to thermal insulation, UPVC windows and doors offer significant noise reduction benefits. This is particularly advantageous in urban areas or near busy roads, where external noise can be a persistent issue. The material’s ability to absorb sound contributes to a more peaceful and quiet indoor environment.

Energy Efficiency in Production and Installation

Manufacturing Process

The production and installation of UPVC are also key factors contributing to its overall energy efficiency. The manufacturing process of UPVC is less energy-intensive compared to materials like aluminium or wood. Furthermore, the ease of installation ensures that there is minimal energy expenditure during the fitting process. The manufacturing of UPVC involves fewer steps and requires lower temperatures than metals, leading to reduced energy usage. This efficiency is further enhanced by the fact that UPVC can be recycled, reducing the need for raw materials and the energy associated with their extraction and processing.

Installation Efficiency

The installation process of UPVC windows and doors is straightforward and quick, thanks to the material’s lightweight and adaptability. This efficiency not only saves time but also reduces the energy and resources needed for installation, further enhancing its eco-friendly profile.

Advantages of UPVC in Insulation

Superior Thermal Insulation: UPVC is known for its excellent thermal insulation properties. Its low thermal conductivity means it is highly effective in preventing heat transfer between the inside and outside of a building. This results in maintaining a stable indoor temperature, leading to reduced reliance on heating and cooling systems, which in turn lowers energy consumption and costs. Airtight Sealing: UPVC frames are designed to fit perfectly, creating airtight seals around windows and doors. This helps prevent drafts and heat loss, further enhancing the insulation efficiency of a building. Longevity and Durability: Unlike traditional materials like wood, UPVC is resistant to weathering, corrosion, and pests. This durability ensures that the insulation properties remain effective over a long period, reducing the need for frequent replacements and maintenance.

Life Cycle and Environmental Impact

Durability and Longevity

A comprehensive assessment of UPVC’s environmental impact involves examining its entire life cycle, from production to disposal. This life cycle analysis helps in understanding the long-term effects of using UPVC in construction. The durability of UPVC is a significant factor in its environmental impact. Its resistance to corrosion, weathering, and pests ensures a long service life, reducing the need for frequent replacements. This longevity means that the environmental cost of manufacturing is spread over a longer period, diminishing the overall impact.

Recycling and Reusability

UPVC is a recyclable material, which significantly reduces its environmental footprint. At the end of its life, UPVC can be ground down and remoulded into new products, thus conserving resources and reducing waste. The increasing focus on recycling UPVC is a testament to the industry’s commitment to sustainable practices.

Comparing UPVC with Other Materials

When considering materials for construction, it’s essential to compare UPVC with alternatives like wood and aluminium. Each material brings unique properties to the table, and understanding these differences is key to making an informed choice.

UPVC vs. Wood

Wood is a traditional choice for windows and doors, known for its natural aesthetic and warmth. However, when it comes to energy efficiency, UPVC outshines wood. Wood can warp and rot over time, leading to gaps and reduced insulation. In contrast, UPVC maintains its shape and efficiency throughout its lifespan. Moreover, wooden frames require regular maintenance, such as painting and sealing, unlike low-maintenance UPVC.

UPVC vs. Aluminium

Aluminium is valued for its strength and slim profile, offering a modern look. However, it’s less efficient than UPVC in terms of insulation. Aluminium conducts heat, potentially leading to higher energy costs. UPVC, with its excellent thermal insulation properties, ensures better energy conservation, making it a more energy-efficient choice.

Innovations and Future Prospects in UPVC Technology

The UPVC industry is not static; it’s constantly evolving with new technologies and innovations. These advancements aim to enhance the material’s energy efficiency and environmental friendliness even further.

Advancements in Energy Efficiency

Recent innovations in UPVC technology focus on improving its insulation capabilities. Developments include more efficient multi-chamber profiles and better sealing techniques, which further reduce heat loss and energy consumption. These advancements ensure that UPVC remains at the forefront of energy-efficient building materials.

Eco-Friendly Innovations

The industry is also making strides towards making UPVC more environmentally friendly. This includes the development of lead-free UPVC and the use of recycled materials in production. Such innovations reduce the environmental impact of UPVC throughout its lifecycle.

Embracing UPVC for a Sustainable Future

UPVC stands out as a highly energy-efficient material for construction, offering superior insulation properties along with durability and low maintenance, making it an excellent choice for eco-conscious consumers. Its continuous evolution in energy efficiency and reduced environmental impact further cements its role as a sustainable option for future construction. Compared to materials like wood and aluminium, UPVC excels in energy conservation and long-term performance. Ongoing innovations in UPVC technology are promising even greater efficiency and sustainability, presenting it as a smart investment for those aiming to minimize their environmental footprint while ensuring building longevity and performance. UPVC’s significance in the construction industry extends beyond functionality; it represents a step towards a more sustainable and energy-efficient future. By opting for UPVC, homeowners and builders play a part in fostering a greener world, one window and door at a time